PRODUCT WARRANTY

Austria energy storage product

Falling prices for battery storage systems, public subsidies and increased motivation on the part of private or commercial investors led to a strong increase in sales of photovoltaic battery storage systems in Austria in 2020. In 2020 for instance, 4,385 photovoltaic battery storage systems with a cumulative usable storage. . Of the total of 875 local and district heating networks surveyed, heat accumulators have been installed as an element of flexibility in 572 heating networks over the last 20 years. Tank water storage systems were used almost. . Heat and cold can be stored in buildings and sections of buildings. If buildings have a large mass and good thermal insulation, this results in thermal inertia that can be used for load shifting. Plastic hoses through which a heat. . The examination covered hydrogen storage & power-to-gas, innovative stationary electrical storage systems, latent heat-accumulators and thermochemical storage.. [pdf]FAQS about Austria energy storage product

Does Austria have a market for energy storage technologies?

A study 1 carried out by the University of Applied Sciences Technikum Wien, AEE INTEC, BEST and ENFOS presents the market development of energy storage technologies in Austria for the first time.

How many photovoltaic battery storage systems are there in Austria?

Of these, approx. 94% were built with public funding and 6% without. The total inventory of photovoltaic battery storage systems in Austria therefore rose to 11,908 storage systems with a cumulative usable storage capacity of approx. 121 MWh.

What are energy storage systems?

Efficient and reliable energy storage systems are central building blocks for an integrated energy system based 100% on renewable energy sources.

How many tank water storage systems are there in Austria?

A total of 840 tank water storage systems in primary and secondary networks with a total storage volume of 191,150 m³ were surveyed in Austria. The five largest individual tank water storage systems have volumes of 50,000 m³ (Theiss), 34,500 m³ (Linz), 30,000 m³ (Salzburg), 20,000 m³ (Timelkam) and twice 5,500 m³ (Vienna).

Does Austria need a green energy system?

In order for the energy system tranformation to succeed, all existing potentials of green energy in Austria are needed. Gas currently accounts for more than 20 percent of total energy demand and stands for 100 percent supply security. Replacing this energy source is neither technically nor economically possible.

Can energy storage systems be used in practical operations?

Innovative storage technologies and new fields of application for the use of energy storage systems are being researched and demonstrated in practical operations as part of national and international research and development activities.

Energy storage product testing system

Large batteries present unique safety considerations, because they contain high levels of energy. Additionally, they may utilize hazardous materials and moving parts. We work hand in hand with system integrators and OEMs to better understand and address these issues. . UL 9540, the Standard for Energy Storage Systems and Equipment, is the standard for safety of energy storage systems, which includes electrical, electrochemical, mechanical and other types of energy storage technologies for. . We also offer performance and reliability testing, including capacity claims, charge and discharge cycling, overcharge abilities, environmental and altitude simulation, and combined. . We conduct custom research to help identify and address the unique performance and safety issues associated with large energy storage systems. Research offerings include: . Depending on the applicability of the system, there will be different standards to fulfill for getting the products into the different installations and Markets. Depending on the area of. [pdf]FAQS about Energy storage product testing system

What is energy storage testing & certification?

Testing and certification services for battery or energy storage systems used in electric vehicles, energy storage and distribution systems, and other large format applications. Our services are designed to help reduce the complexities associated with creating energy storage products.

Who can benefit from energy storage testing & certification services?

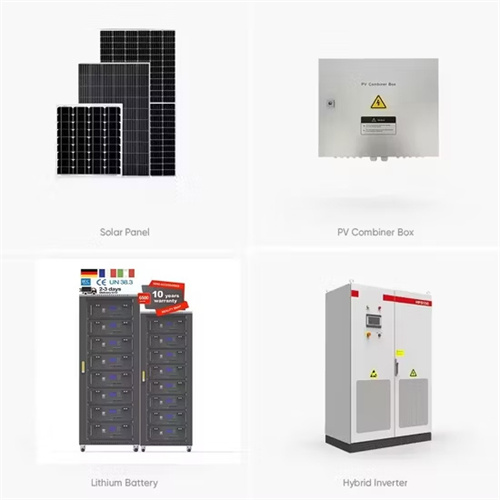

We provide a range of energy storage testing and certification services. These services benefit end users, such as electrical utility companies and commercial businesses, producers of energy storage systems, and supply chain companies that provide components and systems, such as inverters, solar panels, and batteries, to producers.

What is industrial battery & energy storage testing & certification?

Our industrial battery and energy storage testing and certification services can help you address the complexities associated with creating, storing and repurposing battery and energy storage products.

How a comprehensive energy storage system certification is conducted?

Our comprehensive energy storage system certification is conducted according to the following five-step approach: Our global network of experts is extensively experienced in the cross-industry inspection, testing and certification of energy storage systems.

Are energy storage systems reliable and efficient?

Energy storage systems are reliable and efficient, and they can be tailored to custom solutions for a company’s specific needs. Benefits of energy storage system testing and certification: We have extensive testing and certification experience.

What is energy storage systems (ESS)?

Global changes in energy generation and delivery have made Energy Storage Systems (ESS) crucial. CSA Group can evaluate and test your ESS at our advanced laboratories or in the field so you can provide an uninterrupted and safe supply of energy for your customers. Standards offer enormous quality, safety and sustainability benefits.

Photovoltaic grid finished product

Solar manufacturing encompasses the production of products and materials across the solar value chain. This page provides background information on several manufacturing processes to help you better understand how solar works. . Silicon PV Most commercially available PV modules rely on crystalline silicon as the absorber material. These modules have several manufacturing. . The support structures that are built to support PV modules on a roof or in a field are commonly referred to as racking systems. The manufacture of PV racking systems varies significantly depending on where the installation will. . Power electronics for PV modules, including power optimizers and inverters, are assembled on electronic circuit boards. This hardware. [pdf]FAQS about Photovoltaic grid finished product

What is a photovoltaic (PV) solar cell?

Central to this solar revolution are Photovoltaic (PV) solar cells, experiencing a meteoric rise in both demand and importance. For professionals in the field, a deep understanding of the manufacturing process of these cells is more than just theoretical knowledge.

How big is off-grid solar PV?

In the last decade (2008–18), the globally installed capacity of off-grid solar PV has grown more than tenfold, from roughly 0.25 GW in 2008, to almost 3 GW in 2018. Off-grid solar PV is a key technology for achieving full energy access and achieving the Sustainable Development Goals.

How can solar PV be adapted to off-grid applications?

Thanks to its modular and distributed nature, solar PV can be adapted to a wide range of off-grid applications and to local conditions, ranging from lanterns to household systems to village-powering mini-grids.

How are PV solar cells made?

The manufacturing process of PV solar cells necessitates specialized equipment, each contributing significantly to the final product’s quality and efficiency: Silicon Ingot and Wafer Manufacturing Tools: These transform raw silicon into crystalline ingots and then slice them into thin wafers, forming the substrate of the solar cells.

How does Fenice energy make solar panels?

The intricate solar panel manufacturing process converts quartz sand to high-performance solar panels. Fenice Energy harnesses state-of-the-art solar panel construction techniques to craft durable and efficient solar solutions. The transformation of raw materials into manufacturing photovoltaic cells is a cornerstone of solar module production.

How does solar manufacturing work?

How Does Solar Work? Solar manufacturing encompasses the production of products and materials across the solar value chain. While some concentrating solar-thermal manufacturing exists, most solar manufacturing in the United States is related to photovoltaic (PV) systems.

Photovoltaic panel series product introduction

A solar panel is a device that converts into by using (PV) cells. PV cells are made of materials that produce excited when exposed to light. The electrons flow through a circuit and produce (DC) electricity, which can be used to power various devices or be stored in . Solar panels are also known as solar cell panels, solar electric pane. [pdf]

What is the product category of wind blade power generation

Modern wind turbine blades have a twist along the length of the blade. The airfoil's optimal angle of attack is affected by the apparent wind direction. The apparent wind direction changes as the speed of blade increases, even when a uniform wind velocity exists across the rotor swept area. As the tip of the blade travels much. . The tip speed ratio of a wind turbine blade is the ratio of the speed of the tip of the blade to that of the wind. TSR is a vital design criterion for all lift-type wind turbines. As the blades of. . Another method used to increase the efficiency of a wind turbine is the use of a variable pitch control system. The variable pitch control system is used to adjust the pitch of the turbine blades so that the power co-efficient (Cp). . Industrial standards and regulations are critical references used in the design, manufacture, testing, installation, and maintenance of wind turbine blades. Following the guidelines. [pdf]FAQS about What is the product category of wind blade power generation

What is a wind turbine blade?

Wind turbines, the key components of wind energy systems, harness the kinetic energy of the wind and convert it into electrical energy. The design of wind turbine blades is of paramount importance for the overall efficiency and performance of wind turbines.

How many blades does a wind turbine have?

Most turbines have three blades which are made mostly of fiberglass. Turbine blades vary in size, but a typical modern land-based wind turbine has blades of over 170 feet (52 meters). The largest turbine is GE's Haliade-X offshore wind turbine, with blades 351 feet long (107 meters) – about the same length as a football field.

What is a bladeless wind turbine?

Bladeless wind turbines, also known as bladeless vertical-axis wind turbines, represent an innovation in comparison to conventional wind turbine designs. Instead of using classic blades that rotate around a horizontal axis, these devices opt for a vertical axis configuration, eliminating the blades altogether.

Why are wind turbine blades important?

The rapid growth of the wind energy industry has spurred significant advancements in wind turbine technology, particularly in the design and development of wind turbine blades. The efficiency and performance of a wind turbine largely depend on the design of its blades.

How reliable are wind turbine blades?

We know wind turbine blades. Capturing the wind--onshore or offshore, at all speeds, all around the world--calls for wind turbine blade reliability. And reliability comes from experience. LM Wind Power’s technology plays a central role in the creation of each wind turbine blade type.

Who makes wind turbine blades?

Veritas, D.N. Design and Manufacture of Wind Turbine Blades, Offshore and Onshore Turbines; Standard DNV-DS-J102; Det Norske Veritas: Copenhagen, Denmark, 2010. Case, J.; Chilver, A.H. Strength Of Materials; Edward Arnold Ltd.: London, UK, 1959.