Causes of corrosion of energy storage containers

Corrosion of metal containers for use in PCM energy storage

Energy policies are nowadays focused on using solar energy and reusing the waste heat of the industry to use them as a primary energy source. This way, fossil fuel and

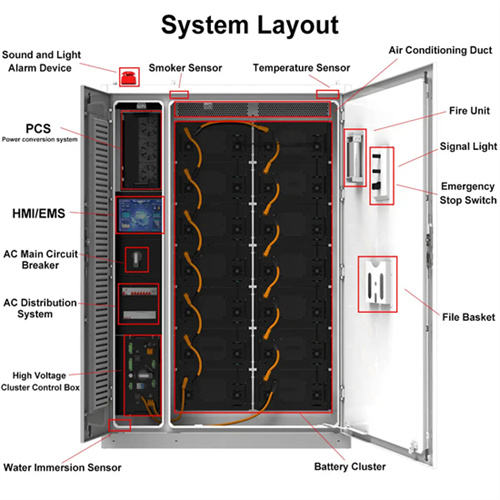

Battery energy storage system container,

Therefore, the overall electrical safety of the lithium battery energy storage container system has a large hidden danger, and it will cause the spread of fire. When a lithium battery burns, a large amount of gas is

Corrosion of Metal Containers for Use in PCM Energy Storage

The use of erythritol to develop a storage system requires understanding its corrosion behavior with storage container material and piping system to ensure the safety of

Hot corrosion behavior of commercial alloys in thermal energy storage

However, the application of molten chlorides at hightemperatures causes additional challenges, particularly increased corrosiveness of metallic containers and structural materials [8-10].

Corrosion, Shedding, and Internal Short in Lead-Acid Batteries: Causes

Lead-acid batteries, widely used across industries for energy storage, face several common issues that can undermine their efficiency and shorten their lifespan. Among

Corrosion of metal containers for use in PCM energy storage

Corrosion of metal containers for use in PCM energy storage . × Close Log In. Log in with Facebook Log in with Google. or. Email. Password Hence caution must 22 be taken when

Corrosion behavior of Fe based container alloys in molten Na

The thermal energy storage container fits tightly with the R-SOCs. The latent heat is released in the SOEC mode and stored in the SOFC mode. the corrosion resistance

Review of research progress on corrosion and anti-corrosion of

This paper reviews the corrosion problems of phase change materials (organic and inorganic) used as energy storage media in latent heat storage systems and compares

analysis of corrosion causes of energy storage containers

This chapter presents the corrosion characterisation methods used for thermal energy storage, in molten salts used in CSP plants and phase change materials (PCM) used for latent energy

EVALUATING CORROSION OF NUCLEAR MATERIAL STORAGE

understand the effects of corrosion on the lifetime of the containers to ensure worker safety. Studies are being conducted on both container types to determine the relative susceptibility of

Corrosion behavior of Fe based container alloys in molten

DOI: 10.1016/j rsci.2023.111616 Corpus ID: 264477576; Corrosion behavior of Fe based container alloys in molten Na2CO3-K2CO3 as thermal energy storage medium for reversible

Corrosion and Materials Degradation in Electrochemical Energy

This review provides recent updates on corrosion and degradation issues and their mitigation approaches in electrochemical energy storage and conversion devices,

Corrosion of Metal Containers for Use in PCM Energy Storage

In recent years, thermal energy storage (TES) systems using phase change materials (PCM) have been widely studied and developed for comfort building applications. The PCM are

Corrosion in Molten MgCl2/NaCl/KCl Chlorides for High

Molten chlorides are promising alternative thermal energy storage (TES) materials to be applied in concentrating solar power (CSP) plants. Their high thermal stability

Corrosion of metal containers for use in PCM energy storage

1 Corrosion of metal containers for use in PCM energy storage 2 22 be taken when selecting it as inorganic salt container. Despite copper has a corrosion 23 rate range of 6-10 mg/cm2·yr in

Renewable and Sustainable Energy Reviews

Thermal energy storage Corrosion Metal container ABSTRACT The thermal energy storage (TES) system using phase change materials (PCMs) has been studied since past three decades.

Corrosion effect of phase change materials in solar thermal energy

The main challenge faced in the TES by the LTS method is the incompatibility of phase changing materials with the storage containers. Moreover, only a handful studies have

Corrosion of metals and salt hydrates used for thermochemical energy

Solar energy can be efficiently used if thermal energy storage systems are accordingly designed to match availability and demand. Thermal energy storage by

A comprehensive review of the materials degradation phenomena

(a) plots of corrosion potential for sample in concrete rebars-control, organic thermal energy storage aggregate-TESA and organic thermal energy storage aggregate

Corrosion behavior of metallic alloys in molten chloride salts for

on corrosion kinetics of the structural alloys and materials Fig. 3 A molten salt storage tank (container) for the Crescent Dunes solar power plant. Size of tank: 12.2 m tall and 42.7 m in

Corrosion of Commercial Alloys in Thermal Energy Storage Material of

In this work, two corrosion mitigation strategies are investigated to alleviate the hot corrosion of structural materials in molten chloride salts: (1) adding corrosion inhibitor and

Corrosion behavior of metallic alloys in molten chloride salts for

thermal energy storage in concentrated solar power plants - A review . Figure 3 shows a molten salt storage tank (container) for this CSP 20 plant, which has huge size, 12.2 meters tall and

DEFINITION AND IMPORTANCE OF CORROSION

understanding of the causes of corrosion and (b) the ways to prevent or at least metallic containers for toxic chemicals, turbine blades and rotors, bridges, and for dis-posal of

Global Impact of Corrosion: Occurrence, Cost and Mitigation

quite often [7]. Corrosion can cause severe failures in boiler tanks, pressure basins, blades of motors/turbines, harmful/aggressive chemical containers, airplane parts,

Corrosion of metal containers for use in PCM energy storage

Downloadable (with restrictions)! In recent years, thermal energy storage (TES) systems using phase change materials (PCM) have been widely studied and developed to be applied as

Corrosion behavior of Fe based container alloys in

Download Citation | On Oct 1, 2023, Junwei Wang and others published Corrosion behavior of Fe based container alloys in molten Na2CO3-K2CO3 as thermal energy storage medium for

BATTERY ENERGY STORAGE SYSTEM CONTAINER, BESS CONTAINER

BATTERY ENERGY STORAGE SYSTEM CONTAINER, BESS CONTAINER TLS OFFSHORE CONTAINERS /TLS ENERGY Battery Energy Storage System (BESS) is a containerized

Corrosion of metal containers for use in PCM energy storage

PCM are normally encapsulated in containers, hence 16 the compatibility of the container material with the PCM has to be considered in order 17 to design a resistant container. Therefore, the

(PDF) Composite laser claddings for corrosion

PDF | On Feb 10, 2021, Pavla Bartoň Klufová and others published Composite laser claddings for corrosion protection of outer surfaces of storage containers for spent nuclear fuel in underground

Causes of Corrosion

Shipment and storage are self-explanatory: allowing metal surfaces to have prolonged exposure to moisture, ozone, salt, and severe temperatures make them more susceptible to corrosion.

Corrosion and Materials Degradation in Electrochemical Energy

Research and development on electrochemical energy storage and conversion (EESC) devices, viz. fuel cells, supercapacitors and batteries, are highly significant in realizing

Corrosion mechanisms in molten salt thermal energy storage for

High temperature corrosion of molten salt containment materials is of great interest for thermal energy storage systems used with concentrating solar power. Mitigating

6 FAQs about [Causes of corrosion of energy storage containers]

What factors influence corrosion in thermal storage systems?

The factors which will most greatly influence corrosion in thermal storage systems are impurity concentration, oxidising atmosphere, thermal gradients in the salt and the materials selection for both the storage media and the structural metal.

Do phase change materials cause corrosion in solar energy storage applications?

Corrosion effect of phase change materials in solar thermal energy storage application [J/OL] Renew. Sust. Energ. Rev., 76 ( 2017), pp. 19 - 33, 10.1016/j.rser.2017.03.018 Corrosion of metal and metal alloy containers in contact with phase change materials (PCM) for potential heating and cooling applications [J/OL]

Which material is the most corrosive for building thermal energy storage PCM?

The results show that copper is the most corrosive material, followed by aluminum, and stainless steel 316 is the most corrosion-resistant material. The corrosion rate is shown in Table 10. Therefore, it is recommended to use stainless steel 316 with the lowest corrosion rate when using dodecanol as building thermal energy storage PCM. Table 10.

Why is corrosion a major problem in phase change materials?

The corrosion problem has become a major problem in the practical application of phase change materials, especially for salt hydrate, which is more serious than organic phase change materials.

How can a thermal energy storage system prevent corrosion?

Carefully controlling impurities, both those that inhibit and facilitate corrosion, is vital for mitigating corrosion. Additionally, the atmosphere under which a thermal energy storage system would operate will consist of either air, carbon dioxide, some form of inert gas, or a judiciously chosen mixture.

Can molten salt containment materials withstand high temperature corrosion?

High temperature corrosion of molten salt containment materials is of great interest for thermal energy storage systems used with concentrating solar power. Mitigating this corrosion is critical for the design, life cycle and economics of these systems and requires understanding the mechanisms which drive corrosion.

Related Contents

- The latest standards and specifications for energy storage containers

- Differences between energy storage containers and switch cabinets

- Protection measures for energy storage containers

- The process of land transportation of energy storage cabinet containers

- Air conditioning system for energy storage containers

- Structural characteristics of energy storage containers

- Energy storage in photovoltaics

- Does photovoltaic EPC have energy storage equipment

- Gree titanium energy storage box price

- How to install energy storage cabinet industrial air conditioner

- Kinetic energy storage system

- Containerized energy storage size