Photovoltaic bracket base production flow chart

Revolutionizing Photovoltaic Bracket Production

In the realm of photovoltaic bracket stamping, we have experienced remarkable growth this year, particularly in expanding our customer base and venturing into overseas markets. Recently, we achieved a significant milestone by securing

What are the processes for the production of high

The bracket production list includes the total number of sets of brackets, the model and quantity of each bracket, the model and quantity of bolts, and auxiliary materials such as spring washers, flat washers, puncture

MECHANICAL PROPETIES AND EXPERIMENTAL STUDY ON FIXEDPHOTOVOLTAIC BRACKET

Abstract: In order to study the mechanica properties of the fixed photovoltaic bracket and its failure under wind load, the full-scale photovoltaic bracket specimen was

Flowchart of manufacturing processes of a m-Si PV

The PV-system solar cells'' top silicon and lower boron layers provide negative and positive potentials respectively to capture energy and make it flow in a circuit [11] [33].

What are the processes for the production of high-quality photovoltaic

Kinsend needs to go through strict process review and production inspection for each photovoltaic support project, the following will take you to understand the main Solar

The Ultimate Guide To How Solar Panels Work: An Illustrated

Solar energy has many benefits that are attractive to both homeowners and businesses. The primary benefit of solar energy is its cleanliness, as it does not generate any

Photovoltaics Report

PV installations was about 26% between year 2013 to 2023. In 2023 producers from Asia count for 94% of total PV module production. China (mainland) holds the lead with a share of about

Brackets for solar panels: supports for fixing the photovoltaic

BRACKETS FOR SECURING PHOTOVOLTAIC PANELS, WITHOUT DRILLING. Sun-Age specializes in mounting solar panels on roof without drilling, as we were the first company in

Flow Chart of Working of the Solar PV Remote Monitoring

The massive-scale solar energy harvesting is getting momentum due to the advancement of the photovoltaic (PV) monitoring system day by day; however, the cost of solar PV equipment is

Photovoltaic ground bracket installation options

The installation selection of photovoltaic ground brackets is mainly based on factors such as the fixing method of the bracket, terrain requirements, material selection, and the weather

Photovoltaic Bracket _Nanjing Chinylion Metal Products Co., Ltd.

Photovoltaic Bracket -Nanjing Chinylion Metal Products Co., Ltd.-Photovoltaic bracket is mainly applicable to distributed power stations, rooftop power stations, household, commercial and

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. This page provides background information on several manufacturing processes to help you better understand how solar works.

Solar Panel Production Process: A Complete Guide

Solar panel manufacturing process: from cell to module. During lay-up, solar cells are stringed and placed between sheets of EVA. The next step in the solar panel manufacturing process is lamination.

(PDF) MPPT Methods for Solar PV Systems: A Critical

sources of energy, the solar energy is a suitable one because it is clean, free from emission and easy to change directly to electricity utilising a photovoltaic (PV) system [2–4].

PV Solar Cell Manufacturing Process & Equipment Explained

Step-by-Step Guide to the PV Cell Manufacturing Process. The manufacturing of how PV cells are made involves a detailed and systematic process: Silicon Purification and Ingot Formation:

Home Page

The company operates three major production bases, encompassing nearly 50,000 square meters of production area. Its main business includes various photovoltaic fixed ground

FUTURO SOLAR

JIANGSU FUTURO SOLAR Co., Ltd. is the world''s leading manufacturer of photovoltaic brackets and aluminum profiles. It mainly produces various types of roof and ground solar brackets,

Flowchart of manufacturing processes of a m-Si PV

Analyzing the complete life cycle of photovoltaic modules: the process of production, operation, and the recycling of solar cell panels and ancillary components, one can demonstrate obvious

Steps and layout of solar module manufacturing

In 2015 we redesigned the layout based on our production lines, with particular attention to three aspects: the optimization of movements from one step to another, maximizing the number of operators and improving

Flow chart of photovoltaic cells warehousing.

Download scientific diagram | Flow chart of photovoltaic cells warehousing. from publication: Development of Photovoltaic Cell Production Information Management System | Due to a

Designing and Simulation of Three Phase Grid-Connected

It is discussed in detail in the following sections, which include the System Specification, Block diagram of grid-tied PV system, Methodology Flow Chart, maximum

Photovoltaic Bracket Market Analysis

3.1 Global Photovoltaic Bracket Sales and Revenue 2019-2030 3.2 World Photovoltaic Bracket Market by Country/Region, 2019, 2023 & 2030 3.3 Global Photovoltaic

Solar panel

Solar array mounted on a rooftop. A solar panel is a device that converts sunlight into electricity by using photovoltaic (PV) cells. PV cells are made of materials that produce excited electrons

Automatic photovoltaic bracket production line 45kw

Automatic photovoltaic bracket production line 45kw equipment Online inquiry The production efficiency is greatly improved. The finished product efficiency can reach 10-30 meters per

PV-Manufacturing

Figure 1: PV module with 36 cells interconnected to form a series string. Figure 2: Schematic of the PV module manufacturing flow. The schematic process flow for the fabrication of a PV module is shown in Fig. 2. In the interconnection step,

Solar Tracking Structure Design

Solar energy is increasing in popularity throughout the world. Germany continues to lead the world in solar power production while breaking its own records year after year [1] despite the nation''s

Solar Photovoltaic Manufacturing Basics

Module Assembly – At a module assembly facility, copper ribbons plated with solder connect the silver busbars on the front surface of one cell to the rear surface of an adjacent cell in a

Solar photovoltaic bracket production process flow chart

Solar photovoltaic bracket production process flow chart. an essential step for thin-film Si PV production. In situ cleaning using gases containing fluorine (F) is a widely adopted process

Large-Scale Ground Photovoltaic Bracket Selection Guide

A-style photovoltaic brackets play a crucial role in photovoltaic systems, with their simple structure resembling the letter "A." They typically feature a one-to-one inclined support design, with the

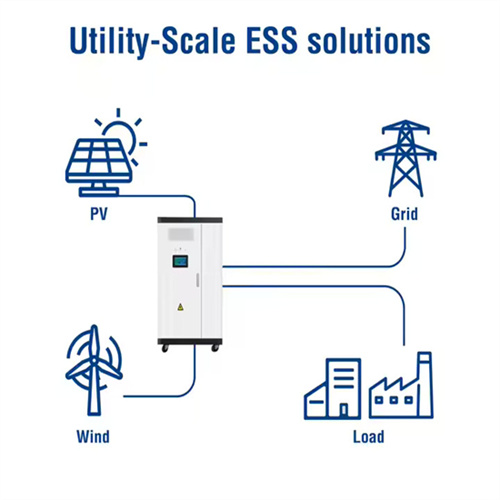

Optimum Energy Flow Management of a Grid‐Tied Photovoltaic

The flow chart in Figure 5 represents the main steps of the algorithm. Figure 5. E RES is the daily power production of PV and wind turbines (kWh). Base GHG

Structural Design and Simulation Analysis of New Photovoltaic Bracket

Save construction materials, reduce construction cost, provide a basis for the reasonable design of PV power plant bracket, and also provide a reference for the structural

Photovoltaic flexible bracket

Photovoltaic flexible bracket is an emerging photovoltaic installation system, which is characterized by its flexibility and adaptability. Compared with traditional fixed photovoltaic

Flow Chart of the Solar Panel Manufacturing Process:

Discover the solar panel manufacturing process flow chart that begins with quartz and ends with photovoltaic prodigies. Learn why crystalline silicon is the backbone of the solar module assembly and cell fabrication

Photovoltaic Tracking Bracket Market Report 2024 (Global Edition)

The base year for the calculation is 2023 and 2019 to 2023 will be historical period. pie charts, tables and bar graphs that explain the data analysis based on current

Flowchart of the Photovoltaic system study

The solar photovoltaic system is an emerging renewable energy resource. The performance of the solar photovoltaic system is predicted based on the historical experimental dataset.

Solar Panel Steel Bracket Roll Forming Machine Photovoltaic

C Steel Purlin Roll Forming Machine Production Line,22~32m/min include punching Other Solar Tracker Steel Purlin Roll Forming Machine Production Line 1.U41 series Steel Purlin Roll

CN117749060B

The invention relates to the technical field of photovoltaic brackets, and particularly discloses a photovoltaic bracket, which comprises the following components: a base; the support...

Structure design and analysis of integrated photovoltaic power

Under three typical working conditions, the maximum stress of the PV bracket was 103.93 MPa, and the safety factor was 2.98, which met the strength requirements; the hinge joint of 2 rows

6 FAQs about [Photovoltaic bracket base production flow chart]

How do photovoltaic panels work?

The creation of photovoltaic panels centers around turning crystalline silicon into solar cells. These cells are part of large solar projects worldwide. Learning about the solar cell manufacturing process shows how we’ve advanced from the first commercial solar panel to today’s advanced modules. These modules power our homes and cities.

What is a photovoltaic (PV) solar cell?

Central to this solar revolution are Photovoltaic (PV) solar cells, experiencing a meteoric rise in both demand and importance. For professionals in the field, a deep understanding of the manufacturing process of these cells is more than just theoretical knowledge.

How are PV solar cells made?

The manufacturing process of PV solar cells necessitates specialized equipment, each contributing significantly to the final product’s quality and efficiency: Silicon Ingot and Wafer Manufacturing Tools: These transform raw silicon into crystalline ingots and then slice them into thin wafers, forming the substrate of the solar cells.

How to create a solar PV production process card?

Turn the solar cell front up and view it from different angles. Put the cells that have the same color and size in different groups. Each group should contain at least 36pcs, 60pcs and 72 pcs of solar cells. Put all the groups in the material tray. Fill the solar pv production process card and stick a barcode on this card.

How does PV Manufacturing work?

It all starts with quartz sand, the main raw material. This sand undergoes a complex reduction process to produce vital gases. These gases are key for making polysilicon, the backbone of PV modules. The journey from rough quartz to polished, efficient photovoltaic panels shows the intricacy of PV manufacturing.

How can solar photovoltaic systems improve the energy curve?

Increasing the flow of energy to and from the local power grid is another step toward a more stable energy curve. During this project, recommendations for software will be developed to design solar photovoltaic systems that are capable of connecting to the grid in three phases, and analysis harmonics.

Related Contents

- Photovoltaic bracket installation construction flow chart

- Photovoltaic bracket delivery flow chart

- Alu-zinc photovoltaic bracket production process

- Photovoltaic bracket production line layout

- Where to buy cheap photovoltaic bracket base

- Does the photovoltaic bracket base have a certificate of conformity

- Outdoor photovoltaic panel installation flow chart

- Price list of photovoltaic bracket welding base

- Photovoltaic panel replacement flow chart

- Jiang roof photovoltaic bracket production

- Homemade photovoltaic panel bracket production

- Photovoltaic bracket base fixing glue