Wind turbine gearbox cooling

Two phase flow evaporative cooling technology for wind turbine

The thermal management of wind turbines is an important guarantee for their long-term stable and reliable operation. This article combines a new type of pump driven two

Development, components & service for wind turbines | HYDAC

From generators to gearboxes to power cables: with our many years of expertise in the wind energy sector, we provide you with innovative solutions for all the challenges relating to your

Monitoring wind turbine gearboxes

The public surveys WMEP 4 and LWK, referred to by Spinato et al., 3 showed that the gearbox exhibits the highest downtime per failure among all onshore WT sub-assemblies, whereas

Wind Turbine Gearbox Technologies

The majority of gearboxes at the 1.5 MW rated power range of wind turbines use a one- or two-stage planetary gearing system, sometimes re ferred to as an epicyclic gearing system. In this

(PDF) Wind Turbine Gearbox Technologies

The reliability problems associated with transmission or gearbox equipped wind turbines and the existing solutions of using direct drive gearless turbines and torque-splitting,

Digital twin-driven online intelligent assessment of wind turbine gearbox

1 INTRODUCTION. Wind power, being a source of renewable energy, holds a significant position in today''s global energy scenario. 1 It contributes to the reduction of carbon

Wind Turbine Components

drive or with gearbox. 11 Wind Turbine Components. In other more sophisticated designs, they are bolted to the pitch bearing, which adjusts lubrication, and cooling systems. 2. Nacelle 15

Ymer – Wind Power

After having secured optimum performance for thousands of wind turbines installed onshore or offshore and in all kinds of operating conditions, we have unrivaled expertise with wind turbine cooling solutions. We design and

(PDF) Cooling Techniques in Direct-Drive Generators for Wind Power

Direct-drive generators are an attractive candidate for wind power application since they do not need a gearbox, thus increasing operational reliability and reducing power

Study and analysis of wind turbine gearbox lubrication failure

The wind turbine structural failure is 17.1%. which included windmill blade, nacelle and tower damages. The other components get failed in 6.9%. These NREL analyze

Optimal preventive maintenance strategies for a wind turbine

For this strategy, our objective is to develop an analytical model to optimize the renewal period of the gearbox considering the balance between the cost of production loss

Optimal preventive maintenance strategies for a wind turbine gearbox

As soon as the latter reaches a predefined threshold level, production rate is drastically reduced by slowing down the wind turbine while cooling the gearbox for a certain

Hydraulic Cooling Systems for Wind Turbines

- Keeping your turbine cool. Key components in your wind turbines become less effective as they heat up during use. Keeping your gearboxes, generators, converters and power packs at the

(PDF) Wind Turbine Gearbox Technologies

Standard horizontal axis wind turbines typically use gearboxes for large-scale applications and direct coupling for small-scale designs to connect the rotor to the generator.

Onshore Wind

Onshore wind – Leading supplier of cooling solutions for onshore wind applications. Customized cooling components, systems & modules. Nissens Cooling Solutions is the preferred

WES

Depending on the type, nominal power, shaft speed, the specific electric loading and subsequently the armature thermal loading, three general solutions – namely, air–air, air–water and water jackets – are commercially

FEM and ANN approaches to wind turbine gearbox monitoring

Condition monitoring (CM) of wind turbine gearbox is one of the key concerns for the reliable operation of wind power generation. With the huge ongoing transition towards

Wind Turbine Gearbox Technologies

8 Wind Turbine Gearbox Technologies Adam M. Ragheb 1 and Magdi Ragheb 2 1Department of Aerospace Engineering 2Department of Nuclear, Plasma and Radiological Engineering,

Components, Systems and Service for Wind Turbines.

for Wind Turbines. With over 7,500 employees worldwide, HYDAC is one of the leading suppliers of fluid technology, Gearbox cooling: Motor pump unit with filtration Gearbox / Generator

Optimization of Heat Dissipation and Control Scheme

The original wind turbine gearbox cooling system and the enhanced seawater cooling system simulation models are built at the same time, and dynamic working conditions simulation research is done

Wind turbine nacelle cooling systems: A review | Request PDF

About 95% of wind turbines use liquid and air cooling methods to keep components inside the nacelle operating normally [16]. The literature indicates that

Wind turbine gearbox oil temperature feature extraction and

The wind turbine gearbox (WTG) is a critical component that is prone to wear and tear. Although the failure rate of WTGs is relatively lower compared to electrical failures,

Aerodynamics and Sustainable AutomotiveTechnology

117 wind turbines catch fire each year because of the overheating of mechanical parts combined with flammable substances inside the body of the turbine being in close proximity. Ogab® offers a solution that provides a reduction in

Wind Turbine Gearbox Lubrication: Performance, Selection, and

• Unfortunately for wind turbine gear oils, there is no universal answer for what is the best oil or type of oil • By properly selecting a proper lubricant for the wind turbine gearbox – Minimize

Cooling Techniques in Direct-Drive Generators for Wind Power

Direct-drive generators are an attractive candidate for wind power application since they do not need a gearbox, thus increasing operational reliability and reducing power

Wind power

Additionally, for both hydraulic pitch turbines and electric pitch turbines we provide cooling systems for the generator, converter, gearbox and nacelle. Hine simplifies assembly and

Cooling Techniques in Direct-Drive Generators for Wind Power

One major design decision is whether to directly connect the generator''s shaft to the wind turbine or to use a gearbox [10,11,12,13,14,15,16]. Both designs have pros and

Offshore Wind

Nissens Cooling Solutions has a proven track record in developing and supplying customized cooling solutions to offshore wind turbine applications. In more than 90% of all offshore wind

WIND TURBINE COOLING: THE STATE-OF-THE-ART REVIEW

wind turbine has a cooling system and a lubrication heater. So, for ensuring normal operation heat exchange rate between gearbox and cooling fluid must be sufficient. The next section of waste

Maximizing Wind Turbine Gearbox Performance with

A business unit of ZF Friedrichshafen, ZF Wind Power is a leader in designing, manufacturing, supplying, and servicing wind turbine gearboxes. Prior to implementing the Simcenter software, ZF Wind Power

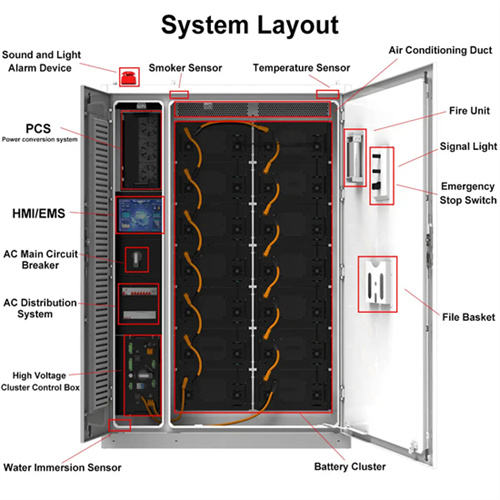

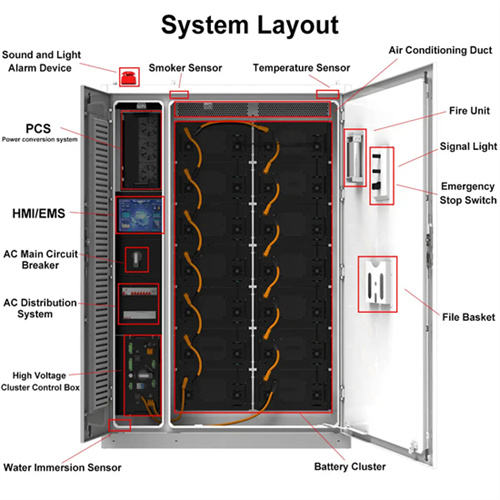

Cooling systems concepts and designs | Wind Turbine System

The main cooling system of a wind turbine is responsible for the complete temperature management of the drivetrain system. design requirements for wind turbine

Gearbox

Wind Turbine Gearbox : Cooling. By Windmills Tech Editor. Heat is generated during the operation of the gearbox due to friction between the solid surfaces of the moving parts. Most of

Development of a 5 MW reference gearbox for offshore wind turbines

The wind turbine gearbox type and design influence other turbine parts, such as the tower and nacelle. Therefore, a systems engineering approach should be consulted. In this

Wind Turbine Gearbox Failure Modes – A Brief

non-uniform cooling or unequal transformation of austenite to martensite. 10 "Wind Turbine Gearbox Condition Monitoring Round Robin." presented at the 2011 Wind Turbine Condition

Modern Wind Turbines: A Lubrication Challenge

A special gearbox oil filter, separate from the normal oil cooling system, ensures high oil cleanliness. This is a key factor in desert or arid conditions where airborne dust can get into

IMPROVING WIND TURBINE GEARBOX RELIABILITY

WHITE PAPER MAY 2017 5 FIGURE 3: Data from National Renewable Energy Laboratory''s gearbox reliability collaborative failure database showing wind turbine gearbox failure

6 FAQs about [Wind turbine gearbox cooling]

How do wind turbines maintain gearboxes?

Conclusion This study was prompted by a maintenance issue that a wind turbine operator in southern Morocco had with maintaining the wind turbines’ gearboxes. They have been maintaining the gearboxes by simply cooling them down automatically whenever their temperature reaches a critical prespecified threshold.

What is wind turbine cooling?

Wind turbine cooling involving: wind generator, electronic and electric equipment, gearbox and other components cooling. Through the years challenges of cooling systems for wind turbine caused the new cooling systems.

How long do wind turbine gearboxes last?

AWEA. While wind turbines are designed for a lifetime of around 20 years, existing gearboxes have exhibited failures after about 5 years of operation. The costs associated with securing a crane large enough to replace the gearbox and the long downtimes associated with such a repair affect the operational profitability of wind turbines.

What is the optimal policy for a wind turbine gearbox?

It has then been made possible to determine the optimal policy (N*, P*) for any given wind turbine gearbox with a given reliability, operated in any specific situation in terms of costs related to maintenance, logistics, cooling, and production loss.

What happens when a wind turbine gearbox is replaced?

Then, after a number of cooling actions during which the wind turbine operates under capacity resulting is a loss of energy production, the gearbox is replaced by a new identical one or submitted to an overhaul. The renewal time is based on the maintenance agents’ personal judgement.

How a wind turbine cooling system works?

In this study, a conceptual design of a new wind turbine cooling system is proposed. In this system, the heat which is generated by wind turbine using a coolant comes to ORC cycle and gives the heat into the refrigerant. After that the coolant goes back to the wind turbine to take the heat.

Related Contents

- Wind turbine gearbox lower tower

- The role of wind turbine balance block

- How many kilowatt-hours of electricity does a wind turbine blade generate in one revolution

- Wind turbine blade listed companies

- How much does a large wind turbine blade cost

- Wind turbine blades are too long

- Wind turbine storage South Georgia and South Sandwich Islands

- Causes of fire in wind turbine generators

- What are the specifications of wind turbine generators

- Battery storage wind turbine Norfolk Island

- Wind turbine generator power generation principle

- Energy storage of wind turbine variable pitch system