Foam sandwich panel photovoltaic fixture

Structural Response of Polyethylene Foam-Based Sandwich Panels

This study analyzes the mechanical behavior of low density polyethylene foam core sandwich panels subjected to edgewise compression. In order to monitor panel response

Fiberglass Foam Sandwich Panels

Manufactured with a with lightweight, high density structural foam, our foam core sandwich panels demonstrate the light weight, high strength and stiffness properties desired in a foam core

Aluminium Foam Sandwich Panels: Metallurgy, Manufacture

Sandwich panels consisting of a highly porous alumin- ium foam core and aluminium-based face sheets are manufactured by roll-bonding aluminium alloy sheets to a

INFLUENCE OF CURVATURE ON FOAM CORE SANDWICH PANELS

INFLUENCE OF CURVATURE ON FOAM CORE SANDWICH PANELS M. A. Battley 1, H. Enoksson 2 1 Industrial Research Limited, PO Box 2225, Auckland, New Zealand 2

Guideline to Core and Sandwich

A simplified comparison between a steel panel and a composite panel is shown under the heading "Basics of sandwich composite," demonstrating and explaining the potential weight savings

On low-velocity impact response of foam-core sandwich panels

The finite element (FE) model of foam-core sandwich structure against the low-velocity impact, comprising the sandwiched specimen and clamped lower and upper plates

DEVELOPMENT OF A PHOTOVOLTAIC INTEGRATED INSULATED CONCRETE SANDWICH PANEL

The panel achieved 82% Degree of Composite Action, which can provide enough strength and stiffness. Solar cells worked properly under service load. Shear-lag effect was observed for the

ASTM C273

An example of a sandwich panel, (two sandwich facings and one core), would be rigid foam insulation that is sandwiched in between two pieces of plywood. The test is a compression based load deflection test but can also be used in the

PaNELTECH Sandwich Panels Assembly Instruction

As standard sandwich panels are delivered to the site packaged in accordance with diagram shown in figures 1 and 2. Figure 1 – applicable to wall sandwich panels and Figure 2 –

Panel Slimsun

Slimsun is an innovative line of Sandwich Panels with Flexible Solar Sheets. The Slimsun Panel is the result of the merger between Hiansa Panel and the Swedish company Midsummer, the European leader in the manufacture of flexible solar

Introduction to Sandwich Structures: Materials and Processing

• What is a sandwich panel? • Sandwich panels are typically constructed from a core material bonded between two thin, high strength face-sheets via adhesives • Core carries the shear

Foam Sandwich Panel via Liquid Di usion

Foam Sandwich Panel via Liquid Di usion Welding Method Cheng Yao, Zhengfei Hu *, Fan Mo and Yu Wang self-made fixture (Span length 200 mm), as shown in Figure 2, according to

Low-velocity impact responses and CAI properties of synthetic foam

facesheets. Ugale et al. [7] compared the impact responses of GFRP thin sandwich panels (thickness of 2.5 mm) and carbon fiber reinforced polymer (CFRP) thin sandwich panels with

Sandwich panel roofs

Sandwich panel roofs are comprised of a thermal insulation that is usually made of rigid polyurethane foam (PUR), rigid polyisocyanurate foam (PIR) or rockwool. It is then

EPP Foam Sandwich Panels

EPP (Expanded polypropylene) foam sandwich panel is a 3-layer structural composite panel with two layers of skin material bonded to a layer of EPP foam core. Its skin material is diverse, you can choose FRP sheet, aluminum sheet,

Effective Design Analysis of Fixture Development for Stitching a

This paper mainly deals with design of fixture used to stitching sandwich panels, which helps to stitch different file orientations such as 900, 450, 900/450/900 and 900/450.

Manufacturing process and manufactured sandwich panels. (a)

The in-plane compression tests were performed using a compression fixture manufactured for testing sandwich panels, similar to those shown in an earlier study [29]. The compression

(PDF) Aluminium Foam Sandwich Panels: Manufacture, Metallurgy

Sandwich panels consisting of a highly porous aluminium foam core and aluminium alloy face sheets are manufactured by roll-bonding aluminium alloy sheets to a

ANALYSIS AND TESTS OF REINFORCED CARBON-EPOXY/FOAM-CORE SANDWICH

be tested using existing test fixtures. Three different types of panels were tested in this study. Eight-inch-square unreinforced panels of the minimum-gage sandwich skin design, were used

Three-Point Bending Fatigue Behavior of Aluminum Foam Sandwich Panels

the same size. The fatigue lives of the aluminum foam sandwich panels with higher-den-sity foam cores were much better than those with low-density foam cores. These

Foam Cored Carbon Fibre Panel

High strength foam cored carbon fibre sandwich panel direct from the UK manufacturer. Motorsport, panelling, exhibitions and more. In stock, fast shipping. Materials, equipment and

The response of sandwich panels with rigid

The aluminum honeycomb structure, unfilled honeycomb sandwich panel, and the sandwich panels filled with three types of polyurethane foam (foam 1: 56.94, foam 2: 108.65, and foam 3: 137.13 kg/m3

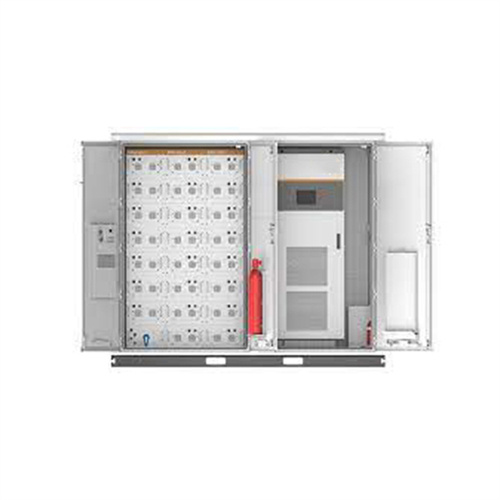

Photovoltaic (PV) Sandwich Roof Panel 950R

This roof sandwich panel type is a special design of PNS company for supporting/installing photovoltaic solar board. It can also be used as a common /ordinary sandwich roof panel. equipped with special fixtures, can realize

Sandwich Panels

Furthermore, sandwich panels with specialised and correctly specified foam cores for the panels application, can have excellent FST (Fire, Smoke and Toxicity) properties. Open-cell Core An

Carbon Fiber Foam Sandwich Panels

Carbon Fiber Foam Core Sandwich Panels are ideal panels for a wide range of applications requiring flat, lightweight and rigid specifications. Skip to content Holiday Closure Our offices

What foam is used in sandwich panels?

By understanding the different types of foam used in sandwich panels, builders and contractors can make an informed decision about which material is the best fit for their specific needs.

Thermoplastic composite sandwich panels with recycled PET foam

Glass fiber composite panels with Polyethylene Terephthalate (PET) foam cores are being widely used in different domains, including wind turbine structures and prefabricated

PVC Foam Sandwich Panels

PVC foam sandwich panel is a typical three-layer structure composite material, the upper and lower layers are skin materials ( fiberglass, aluminum, steel, plastic, plywood, etc.), and the

Everything One Should Now About Sandwich Panels: How to

A sandwich panels building structure can be considered energy efficiency, if its air-tightness comprises less than 1.5 m 3 /m 2 hour. Sandwich panels with integrated

Related Contents

- What are the photovoltaic panel fixture factories

- Ranking of Photovoltaic Panel Gluing Fixture Manufacturers

- Photovoltaic glass sandwich panel

- Photovoltaic panel snow blocking fixture installation requirements

- Paddy field photovoltaic panel transportation artifact

- Photovoltaic panel support implementation plan

- How to detect photovoltaic panel scams

- Domestic solar photovoltaic panel brands

- Photovoltaic panel installation methods and standards

- Grid-connected photovoltaic panel voltage

- Are you looking for a photovoltaic panel installation team

- Ancient photovoltaic panel manufacturers are cheap