Air intake and exhaust requirements for the generator room

Generator Physical Installation and Mechanical Requirements

• Air intake louvers to ventilate the generator room shall be sized to accommodate the amount of combustion air needed by the engine, the amount of cooling air that flows to the radiator and

EMERGENCY GENERATOR ROOM CONTROLS

intake louver room exhaust fan flexible connection d2 d1 plenum scale : date issued : cadd detail no. : detail title /emergency generator room controls december 2008 sd230923-07.dwg

Generator Set Ventilation

Movable louvers positioned to redirect engine heat back into the room until the jacket water temperatures reach 190 F (88 C) may be used. Then, these louvers close so ventilation air is

9.5.8 Diesel Generator Air Intake and Exhaust System

9.5.8 Diesel Generator Air Intake and Exhaust System The diesel generator air intake and exhaust system (DGAIES) provides the diesel prevent the engine from meeting its design

Application & Installation Guide Engine Room Ventilation

• Cooling air for the generator or other driven equipment. A properly designed engine room ventilation system will maintain engine room air temperatures within 8.5 to

Diesel Generator Room Air Flow Rate Measurements using Tracer

The air flow rate through a Diesel Generator Room at a commercial nuclear power facility is commonly a Tech Spec or Design Basis item due to the critical need to

NFPA 110 Standard Overview on Generator Requirements

Chapter 7: Generator Installation Requirements. and exhaust system must be vented to atmosphere to obtain proper room temperature. The room in which the generator is loctaed

GENERATOR ROOM VENTILATION CONTROL SEQUENCE

air dampers exhaust dampers 24v 1 generator room ventilation controls description outside air temperature sensor t-3 room temperature sensor t-1 room temperature sensor t-2 ef-1 fan

Generator Physical Installation and Mechanical Requirements

ventilate the room. • Air intake louvers shall require fast opening before pressurization of the intake plenum to avoid damage to louvers. The combustion and ventilation air intake shall be

Main requirements for ventilation of different rooms on the ships

exhaust air flow must be higher than the sup- requirements [32], the air intake ventilation . a high amount of air is requested for the engine room,

Designing emergency and standby generator systems

Generator sets require combustion and cooling air to enter the generator room or enclosure, and requirements are included in NFPA 110, Chapter 7.7.7. Requirements for

Proper Ventilation for Generators: What You Need to

Choosing the right location for your outdoor generator is crucial for effective ventilation and safety. Here''s what you need to consider: Distance from Buildings: Place your generator at least 20 feet away from buildings,

Unlocking Peak Performance: Diesel Generator

Discover the diesel generator ventilation requirements by delving into the critical aspects of ventilation. Learn about exhaust requirements, enclosure design, and airflow calculations to ensure your generator operates

Commercial Airflow Attenuation

• Air Handling Units • Cooling Towers • Panel Duct Systems • Outside & Exhaust Air Plenums • Generator / Mechanical Room Vents • Barrier Wall and Enclosure Ventilation COMMERCIAL

Generator Room Ventilation | PDF | Ventilation

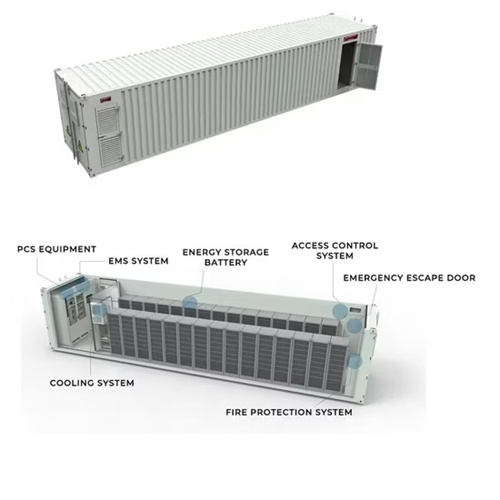

This document provides calculations for sizing ventilation requirements for a generator room and transformer room. It calculates heat loads, required airflow, and intake/exhaust area sizes for different equipment configurations including

Generator Room Ventilation | PDF | Ventilation

Intake and exhaust areas are based on specified air velocities and a louver free area of 50% is used. Total required intake/exhaust areas are presented for the number of active generators and transformers. This document provides

Diesel Generator Room Requirements: Design Considerations

Additionally, they should be placed on a level surface and rest on a raised concrete pad to prevent contact from rising water levels. Avoid locating the generators in

GENERATOR NOISE CONTROL SOLUTIONS

requirements, pressure drop considerations, space air intake openings for the generator room. Targets problems 1 Vibro-Acoustics provides aerodynamic air exhaust openings of the

Design Your Compressor Room: Key Considerations

Design the room with sufficient intake and exhaust vents to maintain a steady flow of fresh air. Consider installing fans or an HVAC system if natural ventilation is

Emergency Generator Room Design | Woodstock Power Company

Placement of exhaust vents also needs to be carefully considered, as distance must be maintained between exhaust output and HVAC air intake areas for the building housing the

Design Generator Rooms for Optimum Performance

A backup generator set is an important line of defense for business owners. Caterpillar offers the industry''s widest range of diesel, gas and rental generator sets, automatic transfer switches,

Unlocking Peak Performance: Diesel Generator Ventilation Requirements

Diesel Generator Exhaust Requirements. The exhaust system of a diesel generator is a critical component that requires careful consideration. The exhaust gases produced during

Exhaust Re-Entrainment Guide

- If the dilution as the air travels from the exhaust to an intake (or other sensitive receptor) takes a route that provides on the order of 75:1 external dilutions, then it is likely that the risk

Where Is the Exhaust on a Generac Generator?

Understanding the significance of proper exhaust setup, choosing an appropriate generac generator exhaust location, routing exhaust and radiator discharge, installing catalytic

Guidelines on Application for Installation of Emergency

generator and the grade of the fuel to be used complies with the requirements of the Air Pollution Control (Fuel Restriction) Regulations, i.e. sulphur content it is essential to locate the

Generator Room Air Intake Calculation

Or calculate the inlet air volume by greater than or equal to 20m3/(kW·h). The exhaust air volume is the intake air volume minus the combustion air volume. The engine combustion air volume

NFPA 110: Installation and Environmental Considerations

These enclosures effectively form an enclosed space around the generator set and can be fitted with sound absorbing foam and air intake and/or exhaust scoops for redirecting noise and

Design Diesel Generator Room for Optimum Performance

1. Determination of diesel generator room: Considering the air intake, exhaust and smoke exhaust of the diesel generator set, the machine room is preferably located in the

01-Fire Pump & Generator Room Calculation | PDF

3) A generator room''s ventilation is calculated based on the generator''s capacity of 1500 KVA, requiring 40,000 CFM of fresh air intake and 36,000 CFM of exhaust air outlet. The document

Importance of Generator Room Ventilation

Generator rooms tend to be in need of air purging as buildup of engine exhaust and other output can be dangerous. Air ventilation systems can also play a role in generator noise reduction. By installing insulated air ducts and using smart

Design Diesel Generator Room for Optimum

Determination of diesel generator room: Considering the air intake, exhaust and smoke exhaust of the diesel generator set, the machine room is preferably located in the first floor if possible. However, the functions of high

Engine room ventilation explained

The pressure then drops so the supply fan turns on. This is how a good engine room ventilation system keeps the balance right. Conclusion. The purpose of an engine room

Sound Attenuation Basics

Sound Attenuated Generator Set Structures. If one of the enclosure''s requirements is sound attenuation then mechanical and combustion air exhaust data must be ascertained prior to making a purchasing decision. This

Generator Room Ventilation Calculator – Calculator

What are the requirements for a diesel generator room? Requirements for a diesel generator room may include proper ventilation, fire safety measures, sound insulation,

6 FAQs about [Air intake and exhaust requirements for the generator room]

What is the intake/exhaust area of a generator?

Intake and exhaust areas are based on specified air velocities and a louver free area of 50% is used. Total required intake/exhaust areas are presented for the number of active generators and transformers. The documents contain calculations for sizing ventilation systems for generator rooms, transformer rooms and engine rooms.

Why do generators need air ventilation?

Air Cleanliness: Ventilation helps to remove harmful fumes and foul odors from any enclosed spaces. Generator rooms tend to be in need of air purging as buildup of engine exhaust and other output can be dangerous. Air ventilation systems can also play a role in generator noise reduction.

Does a generator intake need cool air?

It is important to note that cooling air is needed for more than just the engine; the generator intake also requires cool clean air. The most effective way to do this is to provide a ventilation air source low to the ground at the rear of the package.

Do generator rooms need air purging?

Generator rooms tend to be in need of air purging as buildup of engine exhaust and other output can be dangerous. Air ventilation systems can also play a role in generator noise reduction. By installing insulated air ducts and using smart layout in regards to where air inlet and outlet locations are, noise levels can be controlled.

How should a generator room be ventilated?

Make sure to put all necessary components of a successful ventilation system into place, including air intake and outlet vents, fans, and air ducts. Browse Used Generators By making sure your generator room is properly ventilated, you can keep things running smoothly and prevent dangerous accidents.

How much airflow should a gen set have?

The ventilation system should sufficiently move air to control temperature in all areas of the engine room. The following equations provide the proper airflow (cfm or m3/s velocity for a given gen set installation, assuming 100 F (38C) ambient temperature: Airflow (cfm or m3/s should increase 10 percent for every 2,500 feet (760m) above sea level.

Related Contents

- Design basis for air inlet and exhaust of generator room

- Height difference of air inlet and outlet shaft in generator room

- What is the generator air intake shaft

- Generator air cooler inlet temperature is high

- Solar power generator with air conditioner

- Generator air inlet and outlet

- Household air conditioner solar generator

- Does the generator room need to be ventilated

- Vertical axis generator blade production

- Schematic diagram of trough solar power generator

- Fengjun 54g69 generator fuse

- Oxygen-less game solar generator