Specification requirements for photovoltaic prefabricated pier support

Prefabricated building requirements | Minnesota Department of

Construction of prefabricated buildings, which is governed by the Minnesota State Building Code, are those structures that are intended for use as one- or two-family dwellings or accessory

ENGINEERING SPECIFICATION ReadySpan Prefabricated FRP

The analysis shall support 8 kips on the rear axle and 2 kips on the front axle. C. Snow Load: The manufacturer shall provide structural analysis to support the PSF snow load based on the

PL PIER LIGHT Specifications

Specifications GENERAL: The pier light shall be Model PL, as manufactured by B&B Roadway, (888) 560-2060. APPLICATIONS: The navigation light shall be designed for use as a marine

How to Build a Pier and Beam Foundation:

Pier and beam foundations are constructed using various materials. Selecting materials based on the project requirements is best, as some may be better suited to specific

Seismic performance of a new type of prefabricated bridge pier

Accelerated bridge construction (ABC) is an effective scheme in reducing the construction time and decreasing the social and economic impact due to traffic disruption

What are the HUD minimum requirements for

What are the HUD minimum requirements for foundation footings and piers under a mobile/manufactured home? Tuesday, February 26, 2019 There are two specs, one for piers up to 36" high using single-stacked

IDAHO MANUFACTURED HOME INSTALLATION STANDARD

All used mobile and manufactured homes shall be installed in accordance with the Idaho manufactured home installation standard, as provided by rule pursuant to Idaho

Experimental study on the seismic performance of prefabricated frame piers

The cap beams of all specimens were made of C50 concrete. The vertical main reinforcement of the CIP specimen adopted eight HRB400 reinforcing bars with the diameter

Structural Requirements for Solar Panels — Exactus

These requirements vary depending on the type of installation, such as rooftop or ground-mounted systems, as well as the specific location

Seismic Behavior of Prefabricated Pier Models Connected by

Grouted sleeve connections have the advantage of being easy to mass produce and construct. Therefore, the use of grouted sleeve connections is still a widespread choice for

Caltrans Geotechnical Manual

5.1 Prefabricated Vertical Drains (PVD) and Surcharge Prefabricated Vertical Drains (PVD) (formally "wick drains") are band shaped (rectangular cross-section) geocomposite products

24 CFR 3285.307

(a) General. The piers used must be capable of transmitting the vertical live and dead loads to the footings or foundation. (b) Acceptable piers—materials specification. (1)

(PDF) Seismic performance of fabricated concrete piers with grouted

The seismic performance and design method of fabricated concrete bridge piers limit their applications in complex and harsh environments. In this study, a continuous bridge

Digital Fabrication for DfMA of a Prefabricated Bridge Pier

The data flow of DfMA for a prefabricated pier is depicted in Fig. The twisted column form considering technical specifications of concrete printing, such as overhang

eCFR :: 24 CFR Part 3285 Subpart D -

Pier and footing specifications that are different than those provided in this subpart, such as block size, Prefabricated piers must not exceed their approved or listed maximum vertical or

Study on the seismic performance of prefabricated square pier

Ultra-high-performance concrete (UHPC) has high compressive strength, excellent tensile strength, good toughness, durability, and ductility [[13], [14], [15], [16]] is

6.1.12 Lintels

comply with BS EN 845-2 ''Specification for ancillary components for masonry'', where steel or concrete; be designed in accordance either with Technical Requirement R5 or

The quasi-static test of hollow prefabricated circular pier with

Currently, grouted sleeves connection is widely used in prefabricated piers as a more reliable connection method. Several scholars have studied the response of prefabricated

Steel Support Pier Installation Instructions

Check specific load requirements for footings and pier pads along with wind zone requirements for new or used manufactured units. Steel Support Piers are designed for use as a

Solar Photovoltaic: SPECIFICATION, CHECKLIST AND GUIDE

Renewable Energy Ready Home SOLAR PHOTOVOLTAIC SPECIFICATION, CHECKLIST AND GUIDE i. Table of Contents. needed to support a solar energy system. The following

Ground Mounted PV Solar Panel Reinforced Concrete Foundation

A ground mounted solar panel system is a system of solar panels that are mounted on the ground rather than on the pole is welded to a base plate anchored to a 36" circular concrete pier.

PL-BM BRACKET-MOUNTED PIER LIGHT Specifications

PL-BM BRACKET-MOUNTED PIER LIGHT Specifications GENERAL: The bracket-mounted pier light shall be Model PL-BM, as manufactured by B&B Roadway, (888) 560-2060.

IDAHO MANUFACTURED HOME INSTALLATION STANDARD

idaho manufactured home installation standard developed cooperatively by the state of idaho division of building safety manufactured housing section

Mabey Modular Piers | Mabey

Mabey''s Modular Piers are made using Compact 200 bridge panels, combined with heavy duty pier top grillages & ground beams. Standard Specification. Module height Pier heights

Steel Pier for Mobile Home Foundations

Steel piers are part of the foundation system that will support a mobile or manufactured home once it is placed on a lot. These high-quality painted steel piers are manufactured right here in

Cable Management for Solar Power

bundles of cables to meet the NEC requirements. Over 25 standard CAB designs are offered to safely support large bundles of string wires, DC feeders, as well as AC, data or other cabling.

Mobile Home Structural Inspection Guide

How to Inspect Mobile Homes or Manufactured Housing for Structural Defects: Detailed procedures, defect lists, references to standards. We address mobile home, trailer, or double

PROPOSED GUIDELINES FOR PREFABRICATED BRIDGE ELEMENTS

Specifications and the AASHTO LRFD Bridge Construction Specifications. These guidelines fulfill the majority of the design and construction specification needs for an ABC project. These

6 FAQs about [Specification requirements for photovoltaic prefabricated pier support]

What are the design and engineering requirements for solar panels?

These requirements vary depending on the type of installation, such as rooftop or ground-mounted systems, as well as the specific location and environmental factors. Proper design and engineering of solar panel structures must take into account several factors, such as wind loads, snow loads, and seismic forces.

What are solar photovoltaic design guidelines?

In addition to the IRC and IBC, the Structural Engineers Association of California (SEAOC) has published solar photovoltaic (PV) design guidelines, which provide specific recommendations for solar array installations on low-slope roofs 3.

What are the structural requirements for solar panels?

Structural requirements for solar panels are crucial to ensure their durability, safety, and efficient performance. These requirements vary depending on the type of installation, such as rooftop or ground-mounted systems, as well as the specific location and environmental factors.

How is a ground mounted PV solar panel Foundation designed?

This case study focuses on the design of a ground mounted PV solar panel foundation using the engineering software program spMats. The selected solar panel is known as Top-of-Pole Mount (TPM), where it is deigned to install quickly and provide a secure mounting structure for PV modules on a single pole.

What are the requirements for a PV installation?

Virtually all domestic PV installations will fall under the scope of Part P. Part P requires the relevant Building Control department to be notified and approve the work. There are two routes to comply with the requirements of Part P: Notify the relevant Building Control department before starting the work.

What are the requirements for a solar array?

The pole must be anchored in concrete at least one meter deep in the ground. The pole and mounting structure shall be sufficiently rigid to prevent twisting in the wind or if large birds alight on the array. The support structure shall be able to withstand winds up to 120 km/h (150 km/h in windy areas).

Related Contents

- Photovoltaic panel assembly connection specification requirements

- Construction plan for photovoltaic stone pier without support

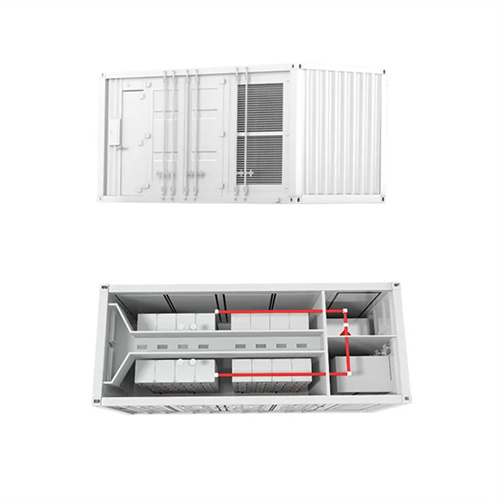

- Export requirements for photovoltaic support containers

- Construction technology of photovoltaic support cement pier

- Photovoltaic support pile test requirements

- Design specification for cast-in-place piles of photovoltaic support

- Qualification requirements for photovoltaic support enterprises

- Photovoltaic support warehouse roof requirements

- Photovoltaic support material requirements and specifications

- Specification of requirements for the number of photovoltaic panels

- Factory photovoltaic panel grounding specification requirements

- Photovoltaic support foundation layout