Photovoltaic support inspection system

Photovoltaic system

A photovoltaic system, also called a PV system or solar power system, is an electric power system designed to supply usable solar power by means of photovoltaics consists of an

Photovoltaic inspection methods

Visual inspection. Visual inspection of a solar system is the simplest method of finding defective PV modules. It basically consists of walking through the rows of modules and

Certified Solar Inspection | American Union of Solar System

Our solar professional will verify system production, test, photograph, and document all system components. Review the Solar Inspection and Valuation Report Utilizing the information from

Solar Panel Repair and Maintenance | Expert solar

Snail trail contamination: Another common problem with solar PV systems is snail trails. This is discoloration on the panels – usually a yellow or brown colour – that occurs after a few years. Solar system inspection and system maintenance

Photovoltaics in Buildings

larger systems and off-grid battery installations. Mechanical design of the PV array is not within the scope of this document. BRE digest 489 ''Wind loads on roof-based Photovoltaic systems'',

Visible defects detection based on UAV-based inspection in large

In an effort to implement large scale inspection of PV systems, recent approaches have used unmanned aerial vehicles (UAV) for the acquisition of high resolution

PV Inspection

While using single-channel IV tracing systems will take a lot of time (days) for inspection of solar farms (e.g. 400 strings for 3 MW) the muti-channel IV-curve tracing system will allow

Photovoltaic System Thermal Inspection using Computer vision

Photovoltaic System Thermal inspection refers to the process of evaluating the thermal behavior of photovoltaic (PV) systems, which are commonly known as solar panel

O&M Teams: Here are the Top 5 Best PV System Inspection

I-V curve tracing (aka electric testing) is the traditional method for inspecting PV systems. It measures the relationship between a module''s current (I) and voltage (V) on a line

太陽能光伏系統安裝指南 Guidance Notes for Solar Photovoltaic (PV) System

Installation of Solar PV Systems in New Territories Exempted Houses (NTEH) (commonly known as village houses) 5.3 在私人樓宇安裝太陽能光伏系統 Installation of Solar PV Systems in

HANDBOOK ON DESIGN, OPERATION AND MAINTENANCE OF SOLAR PHOTOVOLTAIC SYSTEMS

SAMPLE CHECKLIST FOR INSPECTION AND TESTING OF SOLAR PV SYSTEMS 22. Hanboo on Desn Oeaton an Mantenane of Sola Potoolta Sstes 1 1.1 About This Handbook (1)This

A Guide to Photovoltaic Systems Installation: From

Utility Inspection: Once the PV system is installed and before it can be activated, a utility inspector must examine the installation to confirm that it meets all applicable codes and safety

What inspections should be done to your photovoltaic system

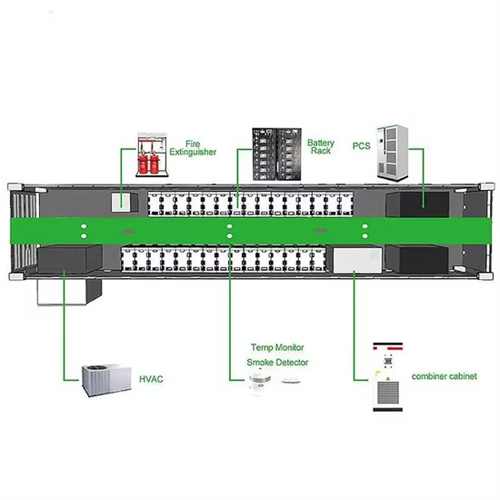

Inspection of photovoltaic support. The function of photovoltaic support in solar power system is to protect photovoltaic modules from being damaged by natural conditions

Solar Panel Maintenance

Visual System Inspection: Thoroughly inspect all electrical hardware and cabling, identifying any potential insurable damage that might affect system performance. Electrical Testing of Solar

(PDF) Review of photovoltaic module degradation,

Most significant defects in PV modules, estimated real PV plant analyses multiplying number of affected modules with severity of detected defects, all scaled to 100%.

PERMITTING, PLAN REVIEW, and INSPECTING FOR PHOTOVOLTAIC POWER SYSTEMS

The second operational part of the inspection cannot be done until the system is connected to the utility. In some jurisdictions, with utility cooperation, both inspections can be

Analyzing the performance of photovoltaic systems using support

The performance of a photovoltaic system depends on several parameters such as temperature, clouds, season, etc. This makes the study of Photovoltaic (PV) performance

Best Practices in Photovoltaic System Operations and

Best Practices in Photovoltaic System Operations and Maintenance 2nd Edition NREL/Sandia/Sunspec Alliance SuNLaMP PV O&M Working Group This work was sponsored

Inspection and monitoring for PV wafer & cell

The LUMI-Q Coating system is specifically designed for pre- and post-coating photoluminescence inspection. It automatically detects defects that affect cell efficiency, allowing users to optimize processes and eliminate defective

Industry best practice manual 2.0

PDF-1.7 %µµµµ 1 0 obj >/Metadata 2020 0 R/ViewerPreferences 2021 0 R>> endobj 2 0 obj > endobj 3 0 obj >/ExtGState >/XObject >/ProcSet[/PDF/Text/ImageB/ImageC

Photovoltaic System Commissioning and Testing

Connected PV Systems – Minimum Requirements for System Documentation, Commissioning Tests, and Inspectiondefines minimum documentation, commissioning tests and inspection

Fault Detection of Solar PV system using SVM and Thermal Image

The work in [37] explores a novel approach to fault detection in solar PV systems. This research uses Support Vector Machine (SVM) algorithms and thermal image

Guide to the Installation of Photovoltaic Systems

of this work with support and assistance from the MCS Solar PV Technical Working Group. Limited licence is given to reproduce images, text and graphics Martin Cotterell is one of the

Solar Photovoltaic: SPECIFICATION, CHECKLIST AND GUIDE

3.5 Provide architectural drawing and riser diagram of RERH solar PV system components. 4 Homeowner Education 4.1 Provide to the homeowner a copy of this checklist and all the

Field Inspection Guidelines for PV Systems

June 2010, Interstate Renewable Energy Council, "Field Inspection Guidelines for PV Systems") Greentech Renewables provides all non-installation services required to pass permitting,

Free Guide to Solar PV Commissioning and Testing

Alongside the expansion of the solar photovoltaic industry, there has been growing concern over the safety and quality of some PV system installations – and particularly in relation to worries that incorrectly installed PV systems can

Inspection systems for the solar industry

Our inspection solutions for solar wafers and cells feature advanced inline monitoring systems for detecting surface defects and verifying geometric measurements. They enable real-time process analysis, enhancing production

Modal analysis of tracking photovoltaic support system

The tracking photovoltaic support system consisted of 10 pillars (including 1 drive pillar), one axis bar, 11 shaft rods, 52 photovoltaic panels, 54 photovoltaic support

Photovoltaic systems operation and maintenance: A review and

The evolving nature of PV system deterioration and fault progression presents a significant challenge in creating precise models and assessing the overall reliability of the

Visible defects detection based on UAV‐based inspection in

2UAV-based inspection system and visible PV modules defects 2.1 UAV-based PV inspection system The implemented UAV-based system for inspection of large-scale PV systems

6 FAQs about [Photovoltaic support inspection system]

Can imaging technologies be used to analyze faults in photovoltaic (PV) modules?

This paper presents a review of imaging technologies and methods for analysis and characterization of faults in photovoltaic (PV) modules. The paper provides a brief overview of PV system (PVS) reliability studies and monitoring approaches where fault related PVS power loss is evaluated.

What is a PV inspection?

The traditional inspection method involves maintenance personnel patrolling the entire PV plant for observing visual defects and/or capturing IR/EL images (using hand-held cameras or tripod system) for the detection of malfunctioning PV modules [ 10, 23 ].

Why is a UAV inspection system important for a PV plant?

Therefore, early fault diagnosis (detection and classification) using a UAV inspection system is crucial for PV plant's O&M to ensure adequate performance, prevent extension of defects to healthy areas and reduce the monitoring cost.

Can photovoltaic modules be diagnosed with multiple visible defects?

The experimental results clearly demonstrate the effectiveness of our solution for photovoltaic modules diagnosis with multiple visible defects. Condition monitoring and fault diagnosis of photovoltaic modules are essential to ensure the efficient and reliable operation of large-scale photovoltaic plants.

What is a visual inspection of a PV module?

Visual inspection is a simplistic method utilised to spot colour changes and to detect visible PV module defects [ 6 ]. Delamination, discoloration, bending, glass breakage and soiling (e.g., dust, dirt and bird droppings) can be detected by visually inspecting PV modules [ 6 ].

Why are condition monitoring and fault diagnosis of photovoltaic modules important?

Abstract: Condition monitoring and fault diagnosis of photovoltaic modules are essential to ensure the efficient and reliable operation of large-scale photovoltaic plants.

Related Contents

- Photovoltaic support equipment quality

- Price of photovoltaic support manipulator

- Photovoltaic support spiral pile cad

- Photovoltaic support wind load paper

- Flexible support photovoltaic foundation

- Photovoltaic support column pile construction plan

- Photovoltaic support civil engineering

- Common Guidelines for Photovoltaic Support C-Shaped Steel

- 550MW photovoltaic support

- Photovoltaic support processing company

- Photovoltaic inverter working condition inspection

- Photovoltaic support steel beam profile