Liquid battery cooling system Ukraine

What is liquid-cooled battery cooling?

The principle of liquid-cooled battery heat dissipation is shown in Figure 1. In a passive liquid cooling system, the liquid medium flows through the battery to be heated, the temperature rises, the hot fluid is transported by a pump, exchanges heat with the outside air through a heat exchanger, the temperature decreases, and the cooled fluid (coolant) flows again.

A review of battery thermal management systems using liquid cooling

Mohsen et al. [52] conducted a study investigating and comparing two distinct module cooling systems: a U-shaped parallel air cooling system and a novel indirect liquid cooling system integrating U-shaped cooling plates. Their findings revealed that liquid-based BTMS exhibited lower temperatures and better temperature uniformity at a given

A comparative assessment of the battery liquid‐cooling system

This work proposes a novel liquid-cooling system that employs the phase change material (PCM) emulsion as the coolant for the battery pack. To compare the proposed scheme with the traditional water cooling system, a thermal model is developed for the battery pack with cooling systems, where the system start-stop control and time hysteresis phenomenon are considered

These Electric Cars Have Liquid Cooled Batteries (Awesome!)

The two preferred systems of cooling are air cooling and liquid cooling, but what is the difference between them? Air Cooling: This method works by using simple convection as a way of transferring heat away from the battery pack. Air runs across the surface of the hot battery, dragging away the heat emanating from it as it moves.

Exploring Types of Battery Cooling Systems

At present, the mainstream cooling is still air cooling, air cooling using air as a heat transfer medium. There are two common types of air cooling: 1. passive air cooling, which directly uses external air for heat transfer; 2. active air cooling, which can pre-heat or cool the external air before entering the battery system.

A liquid cooling plate based on topology optimization and

Currently, indirect contact liquid cooling systems are broadly used. The battery pack''s bottom chamber (also known as the liquid cooling plate), typically made of aluminum alloy, provides both structural support and thermal management [10]. The cooling plate removes the substantial heat generated by the battery pack via the internal circulation

Study on a liquid cooled battery thermal management system

Battery thermal management system (BTMS) is an important and efficient facility to maintain the battery temperature within a reasonable range, thereby avoiding energy waste and battery thermal runaway [1].The liquid cooling systems, with the advantage of high efficiently, low cost, and easy to combine with other cooling component, have been adopted by many leading

Battery Liquid Cold Plate | EV Battery Cooling

Valeo''s innovative battery liquid cooler. Battery energy density increase and fast charging also bring about cooling density increase. Therefore battery coolers need a larger contact surface with the cells/modules and to be

Liquid-Cooled Systems for EV Battery Thermal Management

Liquid cooling system for electrochemical batteries to prevent overheating and thermal runaway. The cooling system uses a specialized liquid cooling board inside the battery pack. It has channels with air-cooled components like L-shaped pipes with pivoting fans. The pipes connect to a booster pump, water tank, and heat exchanger.

A review on the liquid cooling thermal management system of

Liquid cooling, as the most widespread cooling technology applied to BTMS, utilizes the characteristics of a large liquid heat transfer coefficient to transfer away the thermal

Top 10 Battery Liquid Cooling System Companies in Europe

Battery liquid cooling systems are critical to maintaining optimal battery performance and lifetime. At the forefront of automotive innovation and renewable energy, Europe is home to several

Electric Car Battery Thermal Management System -Liquid Cooling System

The cooling liquid has a large thermal capacity and can take away the excess heat of the battery system through circulation, so as to realize the best working temperature condition of the electric car lithium battery pack. The basic components of the liquid cooling system include the electric water pump, electric core radiator (indirect cooling

Top 10 Battery Liquid Cooling System Companies in Europe

Battery liquid cooling systems are critical to maintaining optimal battery performance and lifetime. At the forefront of automotive innovation and renewable energy, Europe is home to several leading companies specialising in battery liquid cooling solutions.

An up-to-date review on the design improvement and

On the current electric vehicle (EV) market, a liquid-cooling battery thermal management system (BTMS) is an effective and efficient thermal management solution for onboard power battery packs and powertrain systems. Its heat transfer efficiency and cooling capacity is theoretically higher than some other mainstream cooling methods such as

Boiling Liquid Battery Cooling for Electric Vehicle

As a new battery temperature control system, "Boiling Liquid Battery Cooling" is developed. The battery cells are immersed in hydrofluoroether liquid; it has high electric

Efficient Liquid Cooling Systems: Enhancing Battery Performance

In addition to improving battery performance and longevity, efficient liquid cooling systems can also have a significant impact on the safety of battery-powered devices

Battery Liquid Cold Plate | EV Battery Cooling

Valeo''s innovative battery liquid cooler. Battery energy density increase and fast charging also bring about cooling density increase. Therefore battery coolers need a larger contact surface with the cells/modules and to be integrated

Performance analysis of liquid cooling battery thermal

An efficient battery thermal management system can control the temperature of the battery module to improve overall performance. In this paper, different kinds of liquid cooling thermal management systems were designed for a battery module consisting of 12 prismatic LiFePO 4 batteries. This paper used the computational fluid dynamics simulation as

A Review of Cooling Technologies in Lithium-Ion Power Battery

Among various cooling technologies, the air-cooling system boasts the most economical manufacturing costs and a compact, reliable structure. The heat transfer coefficient of the

A systematic review and comparison of liquid-based cooling

Guo, A lightweight multichannel direct contact liquid-cooling system and its optimization for lithium-ion batteries, IEEE Transactions on Transportation Electrification, № 8, с. 2334

Boiling Liquid Battery Cooling for Electric Vehicle

As a new battery temperature control system, "Boiling Liquid Battery Cooling" is developed. The battery cells are immersed in hydrofluoroether liquid; it has high electric resistance, non-inflammability, and environmental friendliness and also the boiling temperature is close to the battery operating temperature.

Effect of liquid cooling system structure on lithium-ion battery

In research on battery thermal management systems, the heat generation theory of lithium-ion batteries and the heat transfer theory of cooling systems are often mentioned; scholars have conducted a lot of research on these topics [4] [5] studying the theory of heat generation, thermodynamic properties and temperature distributions, Pesaran et al. [4]

Liquid-Cooled Systems for EV Battery Thermal Management

Liquid cooling system for electrochemical batteries to prevent overheating and thermal runaway. The cooling system uses a specialized liquid cooling board inside the battery

Efficient Liquid Cooling Systems: Enhancing Battery Performance

In addition to improving battery performance and longevity, efficient liquid cooling systems can also have a significant impact on the safety of battery-powered devices and systems. By keeping the battery temperature within a safe range, liquid cooling systems can reduce the risk of thermal runaway and other safety hazards.

Battery Cooling Solutions

What is an EV Battery Cooling System? EV Battery Cooling systems typically feature a liquid cooling loop specifically designed to be the most efficient method of heat transfer in the smallest, lightest form factor possible. Added weight

A systematic review and comparison of liquid-based cooling system

Guo, A lightweight multichannel direct contact liquid-cooling system and its optimization for lithium-ion batteries, IEEE Transactions on Transportation Electrification, № 8, с. 2334 https://doi /10.1109/TTE.2021.3131718

Recent Progress and Prospects in Liquid Cooling

Nanoparticles and liquid metals can significantly improve thermal conductivity and become ideal candidate materials for BTMSs. Compared with water cooling systems, BTMSs based on nanofluid and liquid metal are able to

A systematic review and comparison of liquid-based cooling system

To further improve the thermal performance of the hybrid system of liquid/PCM cooling scheme, the cooling strategy was changed according to the PCM temperature in Ref. [85]. Design of the structure of battery pack in parallel air-cooled battery thermal management system for cooling efficiency improvement. Int J Heat Mass Tran, 132 (2019),

(PDF) A Review of Advanced Cooling Strategies for Battery

In the indirect liquid cooling-based battery thermal management system, the cooling liquid has no direct contact with the battery cell surface, but heat exchange between the battery and the

The Shift to Liquid Cooling Systems for EVs and Beyond | KUS

The shift toward liquid cooling systems in high-performance battery applications is a testament to their effectiveness. This trend is not just confined to the automotive industry — similar systems are increasingly used in battery compartment units and electric generators, as well as data centers to manage server-generated heat.

Recent Progress and Prospects in Liquid Cooling Thermal

Nanoparticles and liquid metals can significantly improve thermal conductivity and become ideal candidate materials for BTMSs. Compared with water cooling systems, BTMSs based on nanofluid and liquid metal are able to keep the battery temperature in a much lower range and show excellent cooling performance under extreme conditions.

A review on the liquid cooling thermal management system of

Liquid cooling, as the most widespread cooling technology applied to BTMS, utilizes the characteristics of a large liquid heat transfer coefficient to transfer away the thermal generated during the working of the battery, keeping its work temperature at the limit and ensuring good temperature homogeneity of the battery/battery pack [98]. Liquid

A Review of Cooling Technologies in Lithium-Ion Power Battery

Among various cooling technologies, the air-cooling system boasts the most economical manufacturing costs and a compact, reliable structure. The heat transfer coefficient of the liquid-cooling system is very high, while the temperature remains uniform in the PCMs cooling system during the material phase transition process.

(PDF) A Review of Advanced Cooling Strategies for

In the indirect liquid cooling-based battery thermal management system, the cooling liquid has no direct contact with the battery cell surface, but heat exchange between the battery and the

6 FAQs about [Liquid battery cooling system Ukraine]

Can direct liquid cooling improve battery thermal management in EVs?

However, extensive research still needs to be executed to commercialize direct liquid cooling as an advanced battery thermal management technique in EVs. The present review would be referred to as one that gives concrete direction in the search for a suitable advanced cooling strategy for battery thermal management in the next generation of EVs.

Which cars use liquid cooling systems?

The Chevrolet Volt and BMW i3 and i8 also use liquid cooling systems for battery thermal management to avoid excessive battery temperature . In addition, 3M has developed a battery direct liquid cooling system for electric vehicles, which immerses the battery module directly into the coolant, showing an excellent cooling effect .

What is a direct liquid cooling system?

In the direct liquid cooling system, the coolant and the battery are in direct contact, which makes the heat transfer process more effective and simplifies the structure of the system and reduces the contact thermal resistance. The coolant in direct liquid cooling systems should be well-insulated, non-flammable, and environmentally friendly.

Can cooling strategies be used in next-generation battery thermal management systems?

The commercially employed cooling strategies have several able maximum temperature and symmetrical temperature distribution. The efforts are striving in current cooling strategies and be employed in next-generation battery thermal management systems. for battery thermal management in EVs.

How to improve the cooling performance of a battery system?

It was found that the cooling performance of the system increased with the increase of contact surface angle and inlet liquid flow rate. For the preheating study of the battery system at subzero temperature, they found that a larger gradient angle increment was beneficial to improve the temperature uniformity.

Should battery preheating be considered in the future liquid cooling research?

The preheating function of the system should also be considered in the future liquid cooling research. In the study of battery preheating, although liquid preheating technology has been applied in electric vehicles, it is still a challenge to preheat batteries efficiently and safely.

Related Contents

- High voltage battery cooling system Ukraine

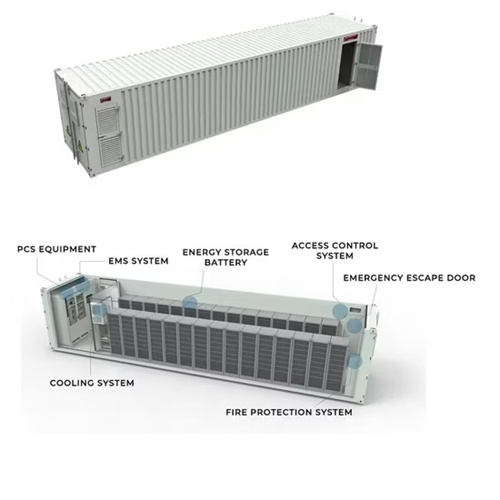

- Installation of liquid cooling pipeline for energy storage battery cabinet

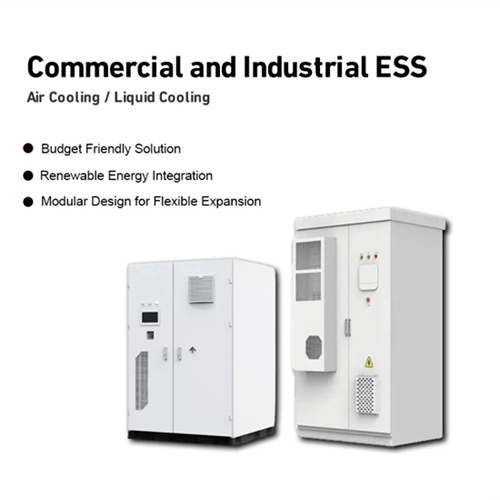

- Which manufacturers of energy storage liquid cooling systems are there

- Lithium battery storage Ukraine

- Ukraine 50kwh battery storage

- How to load liquid cooling energy storage pack into container

- Does power storage require a liquid cooling system

- What does energy storage liquid cooling system mean

- Energy storage cabinet liquid cooling unit water pump pressure

- How many liters does the liquid cooling energy storage cabinet standard have

- Liquid Cooling Energy Storage System Huawei

- Energy storage lithium iron phosphate battery liquid