Aluminum honeycomb panel photovoltaic module

Honeycomb structures as backsheets for light weight PV modules

The integration of photovoltaic modules (PV) into existing infrastructure and/or buildings faces challenges, one of them is the weight of standard PV modules, that can reach

PV/T collector with honeycomb heat exchanger

A photovoltaic/thermal (PV/T) collector is a device formed by a PV module with an attached thermal unit on its back, which allows the simultaneous generation of electric energy and

Honeycomb Core Panel Skins: Aluminum, Steel, Laminate

ALUMINUM is a common metal skin that is used for both industrial and non-industrial honeycomb panel applications. ALUMINUM HONEYCOMB PANEL SKINS ARE AVAILABLE IN A WIDE

Experimental analysis of solar panel efficiency improvement with

The effectiveness of the PV-PCM system as measured by analytical and computational research using PCM encased in an aluminium honeycomb construction in order

A lightweight plastic to replace aluminum module frames

"Solar panel frames made of plastic have many advantages that differentiate them from existing frames, such as ease of installation, and therefore has great market

Thermal management of photovoltaic module with metal matrix

The performance of PV–PCM model was simulated with ESP-r software by Machniewicz et al. [9] and concluded that although this combination serves the purpose,

DAIICHI Products: Aluminum Honeycomb Panel

The aluminum honeycomb panel is a sandwich panel consisting of two aluminum plates as surface sheets and hexagonal aluminum honeycomb cells as the core supporting material,

Structural Optimization and Thermal Management with PCM‐Honeycomb

Phase change material (PCM) as the energy storage material has been utilized in battery module, and the aluminum honeycomb is combined with PCM to improve the heat

An improved design of photovoltaic/thermal solar collector

An improved photovoltaic/thermal (PV/T) solar collector combined with hexagonal honeycomb heat exchanger was studied. It is a combination of photovoltaic panel

Structural Optimization and Thermal Management with PCM

Air PV module Battery Controller Junction box x z y (a) Aluminum honeycomb Air PV module Battery Controller Junction box Wind x (b) Figure 2: The schematic of the PV–battery

Simplifying the solar panel with composites | CompositesWorld

The group determined that EconCore''s ThermHex thermoplastic honeycomb panel, made of DuPont Zytel polyamide resin film, with panel faceskins made with DuPont

Architectural solar facades, reimagined

With a robust aluminum honeycomb core and a layer of high-efficiency solar cells, each panel is a powerhouse of clean energy. But the magic lies in the customizable facing– a canvas where

Cooling Methods for Solar Photovoltaic Modules Using Phase

Aluminum matrix, with honeycomb structure filled with paraffin wax PCM, was placed on the back side of PV module to store the heat generated by the PV module. Figure 7

Optimization of Photovoltaic Thermal Collectors Using Fins: A

At a flow rate of 40 g/s and a temperature of 55.10℃, they may enhance the heat removal process and temperature uniformity. Aluminum heat sinks on PV panels were

A Study of PV/T Collector with Honeycomb Heat Exchanger

A PV/T system is a combination of photovoltaic panel and solar thermal components in one integrated system. into the channel located under the PV module. Air is

Thermal performance of an aluminum honeycomb wallboard

To illustrate its applications, we attached the mPCM + honeycomb module to the back of PV panels. The mPCM + honeycomb module became the heat dissipation module for

Honeycomb Core Panels

Kerr Panel specializes in designing and manufacturing honeycomb core panels made from all types of materials to fit any project, including aluminum, Nomex, foam, and polypropylene.

Structural Optimization and Thermal Management with PCM‐Honeycomb

It is worth noting that the differences between G–PBIS and H–PBIS were that several additional aluminum honeycombs filled with space other than the battery array, the

Thermo-mechanical stability of lightweight glass-free photovoltaic

Thermo-mechanical and electrical stability of lightweight PV modules based on PO and aluminum core. Structural analysis of the adhesive bond in a honeycomb core

An improved design of photovoltaic/thermal solar collector

It was observed that the aluminum honeycomb is capable of enhancing the thermal efficiency of the system efficiently. At mass flow rate of 0.11 kg/s, the thermal

Optimum Design of Solar Sandwich Panels for Satellites

For single objective function by using Excel Solver program, the optimum aluminum sandwich panel which ensuring the minimum weight is (2.2934 kg), with optimum

Photovoltaic Basics (Part 1): Know Your PV Panels for Maximum

Monocrystalline silicon has to be ultrapure and has high costs because its manufacturing process is very complex and requires temperatures as high as 1,500°C to melt

Thermal management of photovoltaic panel by honeycomb-like

A novel aluminum honeycomb structure is proposed for photovoltaic panel thermal management. • Compared to panels cooled without the honeycomb, it achieves a 10

Solar Photovoltaic Systems: Integrated Solutions from Frames, Panel

Chalco provide 6061, 6063, 6005, 6082 etc. aluminum for Solar panel frame and Solar PV support with CEE and TUV certification; also provide transformer strip for the electrical system.

Shingled design lightweight photovoltaic modules using honeycomb

The PV module incorporated a p-type c-Si solar cell, and a shingled-type array structure was applied to maximize the solar-to-power conversion within a limited area [15, 16]. Generally, a

Shingled design lightweight photovoltaic modules using honeycomb

The PV module incorporated a p-type c-Si solar cell, and a shingled-type array structure was applied to maximize the solar-to-power conversion within a limited area [15,16]. Generally, a

Structural Optimization and Thermal Management with PCM-Honeycomb

Phase change material (PCM) as the energy storage material has been utilized in battery module, and the aluminum honeycomb is combined with PCM to improve the heat

Photovoltaic (PV) Module and Its Panel and Array

The photo-voltaic (PV) modules are available in different size and shape depending on the required electrical output power. In Fig. 4.1a thirty-six (36) c-Si base solar

Honeycomb installed at the back of PV module

Download scientific diagram | Honeycomb installed at the back of PV module from publication: Performance Study of Air-based Photovoltaic-thermal (PV/T) Collector with Different Designs

Related Contents

- What is the type of photovoltaic module panel

- Photovoltaic panel inverter module wiring diagram

- How much does the aluminum frame around the photovoltaic panel cost

- Photovoltaic panel aluminum slot installation

- Solar photovoltaic panel aluminum frame production

- Aluminum electrolytic DC photovoltaic panel manufacturer

- Photovoltaic module crystal panel model

- Photovoltaic panel aluminum price trend chart

- Black crystal module photovoltaic panel manufacturer

- Photovoltaic module panel composition

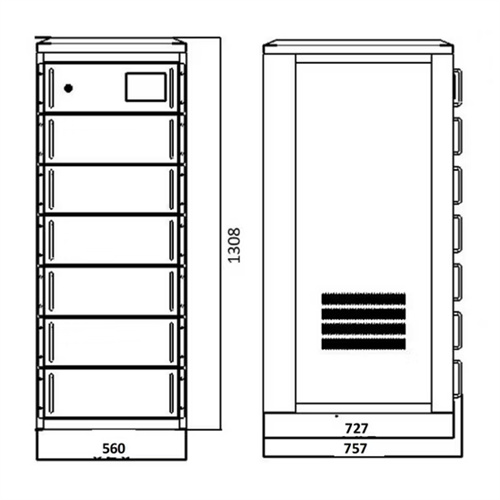

- Photovoltaic panel aluminum frame size drawings

- Rooftop aluminum magnesium manganese photovoltaic panel